Here we have what has to be the ultimate starship Enterprise: the Polar Lights 1/350th scale kit, all new, completely redesigned based on the latest restoration of the studio model at the Smithsonian Institution.

There are a few variations of this model available, for various incarnations of the Enterprise. The one I have is the 50th anniversary edition featuring, for example, the smooth sausar section (no grid lines).

Something I find interesting about this kit is that unlike previous kits, or indeed most kits of fictional craft, this model is not designed after how the Enterprise looked on TV. Rather it is designed as a highly accurate (warts and all) model of the 11 foot filming miniature used in production of the original series. It is as it were, not a model of a starship but a model of a model of a starship. This creates many interesting options and choices as the project goes along.

The scale of this model to the actual model is, I am not sure, something between 1/4th and 1/5th (?), yielding a model about 3 feet long. Yes, it's big.

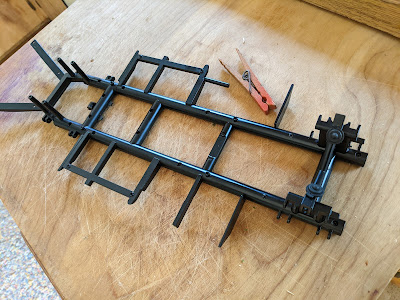

I will be using extra photo etch and the Polar Lights lighting kit, probably mostly out of the box.

The first order of business is to prep, prime and paint the saucer section. This thing is huge!

The plastic has to be cleaned up. Then primered. The inside paint will be a black primer followed by white. The insides need to take care of most of the light blocking.

The outside gets a cycles of primer and sanding after the plastic is all trimmed, cleaned up and lightly sanded.

My kit has some flash in the windows. I'm using just right sizes of round and square watchmakers files to clean them up. These tools make it easy, and accurate.

I thought for a long time about how to do the windows. The first thing I tried was taping over the outside and filing the windows openings with a U/V resin. This didn't work. This thing is so big, and the parts so thick, that I could get the resin all the way down in the window hole from the back.

So I went ahead and put on of the clear pieces provided in the in place.

I wasn't happy with this because the clear plastic does not always come all the way through and fill the opening.

So, with the clear piece in place, I carefully filled the outside with a tiny, leveled off, bit of U/V resin and hardened it up.

After some sanding on the outside surface with 1500, and then 3000, the windows are completely flush and look good!

There are bubbles in the plastic in this piece, but it won't show once I defuse the "clear" some.

I'm pretty happy with this technique, but it does take some practice. The second set I did came out better, and then a more complex group that included rectangular windows came out not so great. I think it's the way to go though. The completely smooth surface this creates is a fantastic effect.